Washing Machine Repair

PROBLEMS COMMON TO ALL WASHER BRANDS

Washing machine designs vary widely, but there are some things that all washers have in common. For example, all washers have an electric motor. All washers have both spin and agitate cycles. And since both cycles are driven by the same electric motor, all washers have some sort of mechanism to change between the two.

All washers must also have a way of filling the tub with wash water and a way of draining out used wash water.

And incidental to this, all washers must have a way of controlling water level in the tub, to prevent spillage by overfill or by centrifugal force during the spin cycle.

All washers must (by law) have a mechanism that brakes the spinning basket at the end of the spin cycle, or else a lid lock to prevent the lid from being opened during or shortly after the spin cycle.

And last but not least, all washers must have a timer that controls and coordinates the start, stop and duration of the various cycles.

FILL CYCLE

During the FILL cycle, a solenoid-operated water mixing valve opens and allows hot or cold water (or both) to enter the tub. There is no pump operating at this time; the tub fills strictly from house pressure.

Similarly, there is no heater in your washer; the heat comes from the water heater in your home.

When the water in the tub reaches a certain level, a pressure switch closes the water solenoid valve(s).

WASH/RINSE

(AGITATION) CYCLE

After the water valve closes, an electric motor starts which drives the transmission, sometimes through a belt, and in some cases through a clutch arrangement, too. The transmission converts the rotary motion of the motor to the back-and-forth motion of the agitator. A driveshaft extends from the top of the transmission to the agitator, where it is connected to the agitator, usually by a spline. (See Figure G-1.)

Agitation will continue for a certain amount of time, which is controlled by the timer. During agitation, some washers use their pump to circulate water, sucking it from the bottom of the tub and pumping it to the top of the tub. The pump is driven by the same electric motor.

Also during the agitation cycle, bleach or softener may be automatically added. This is usually done by a solenoid valve that allows some of the recirculated water to flush out the bleach or softener dispenser. In some models there is no water circulation involved; the solenoid simply opens a valve or door that lets the dispenser contents drop into the wash water. The timer tells this solenoid valve when to open.

SPIN AND DRAIN CYCLES

After agitation comes a drain cycle, sometimes combined with a spin cycle. During the drain cycle, the pump sucks water from the tub and sends it down the drain. During the spin cycle, the same motor that drove the agitator now drives a spin tube

which is concentric with the agitator shaft. (See Figure G-1) The spin tube spins the basket, slinging excess water out of the clothes by centrifugal force. There is a clutch arrangement which allows the basket to come up to speed slowly. This prevents a heavy load from being thrown onto the motor suddenly. It also allows a "pre-pump" action; the water has a chance to drain out of the tub before the basket gets up to speed, preventing the water from overflowing the edge of the tub by centrifugal force.

Some brands have a partial drain cycle only, then refill and agitate again. Some start spinning and draining at the same time. Some only drain until the water reaches a certain level, then start spinning. Most brands have lid switches that prevent the basket from spinning when the lid is open. Some brands have a lid lock that prevents you from opening the lid when the basket is spinning.

At the end of the spin cycle, or whenever the lid is lifted, most models have a braking arrangement that stops the tub from spinning. This helps to prevent people from accidently sticking their hands into a spinning basket.

CAUTION: NEVER BYPASS THE LID SWITCH, EXCEPT FOR TEST PURPOSES. IF IT IS DEFECTIVE, INSTALL A NEW ONE. THEY ARE THERE FOR A REASON. NO JOKE: I PERSONALLY HAVE A NEPHEW WHOSE ARM WAS TORN OFF (AT 2 YEARS OLD) BECAUSE OF A BYPASSED LID SWITCH!

The basic components of the fill system are the hoses, the fill valve, and the pressure or float switch.

The fill valve (Figure G-2) is simply a solenoid valve that opens when activated and allows hot and/or cold water to flow into the tub. Most modern washers use dual solenoid valves, which have both hot and cold solenoids in one valve body. When warm water is desired, both valves open to mix hot and cold.

In the newest digital washers, water temperature may be controlled by a "thermistor." A thermistor is a variable resistor; a resistor whose resistance varies according to what temperature it senses. The thermistor's signal goes to the washer's control board (computer,) which opens or closes hot and cold water valves to control the incoming water temperature.

When the water in the tub reaches the desired level, the pressure or float switch closes the circuit to the fill valve. Float switches are pretty rare; you'll find them only in older washers. A diaphragm-type pressure switch is more common. Typical float and pressure switches are shown in Figure G-3. A few old washers used a pressure switch mounted on the BOTTOM of the tub; these are known as water weight switches. They are rare.

DIAGNOSIS

If your washer is not filling properly, or is overflowing, there could be several reasons.

SLOW OR NO FILL, OR WATER TOO HOT

OR TOO COLD

If your washer is filling very slowly or not at all, or the water temperature is always too hot or too cold, check the fill hose and valve strainers. These are little screens placed in the fill hose and/or water valve to prevent rust and scale from your house's piping system from getting into the water valve. The strainers can get clogged up over time and prevent water flow.

Shut off the water valves and remove the hoses. Look into the both ends of each hose and into the water valve mounted on the washer. In at least one of the three places you should see a strainer screen. (Figure G-4) If it is clogged, you can try cleaning it out with a toothbrush and/or a turkey baster. If you cannot clean the screen sufficiently, you may need to replace it.

In some instances, the screen is non-removable, and you will need to replace the hose or valve. Neither is very expensive.

When re-installing the hoses, always use new hose washers. Also, take care not to overtighten the hose on the plastic threads of the solenoid valve; tighten just enough to stop it from leaking.

If there is any question about the watertight integrity of the hose, replace it. A hose costs a lot less than a new floor or carpeting, which is what you'll be buying if it breaks while you're not home.

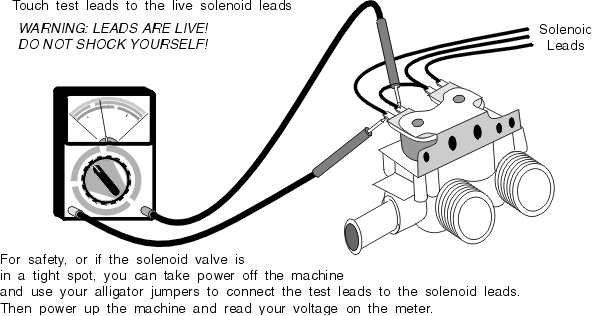

If the strainers look O.K., set your temperature control to "warm" and set your timer in the fill cycle. Raise the lid of the washer and depress any lid switch with a pen or screwdriver. Feel the water entering the washer. If it is too hot or too cold, or if no water is coming out at all, test for voltage across each solenoid coil of the water valve as shown in figure G-5. It should read 110 to 125 volts.

If so, you're getting power to your valve, but it's not opening. Replace the valve.

If you're not getting power to the valve, refer to the wiring diagram for your machine (see section 2-6) and trace the source of the interruption. Sometimes it's a broken wire, but more commonly, there will be a problem with the water level switch, timer, lid switch, or temperature switch. Replace the defective switch.

If your washer is a late-model digital machine with a fill thermistor, a defective thermistor might be sending the wrong signal to the control board. Replacing the thermistor (they're not too expensive) will usually solve the problem. The control board may also be defective.

CAUTION: On some brands, you must raise the top of the cabinet to get to the solenoid valve. If your washer has a mercury-tube type lid switch, raising the top of the cabinet may have the same effect on the lid switch as raising the lid. Your washer may not fill or cycle. You will need to jumper the mercury switch to perform any tests when the cabinet top is raised.

OVERFILL

As the tub fills, water pressure increases at the bottom of the tub. This pressure is transmitted to the diaphragm in the water level switch by a rubber or plastic tube.

(Figure G-6) When the tub reaches the right level, the diaphragm trips the switch, closing the solenoid fill valve and starting the agitate cycle.

If the tube or diaphragm is leaking badly, the water level switch will not sense any pressure, and thus will not shut off the water flow, so the tub will overflow. If this tube is leaking slowly, the washer may exhibit odd fill symptoms. For example, depending on how fast the air leak is, the washer may fill and start agitating, then stop agitating and fill some more, then agitate some more, and so forth, until the washer overfills.

CAUTION: Whenever you remove the tube from the switch, or insert the tube onto the switch, there cannot be any water in the tub or tube. Before you insert the tube onto the switch, blow into the tube first, to clear it of any water that might have gotten in it. ANY WATER REMAINING IN THE TUBE WILL CAUSE YOUR WASHER TO OVERFILL, OR PROBABLY EVEN TO OVERFLOW!

Also test the water level switch electrically, as described in section 2-6(b).

DOES NOT STOP FILLING, AND/OR WATER LEVEL KEEPS GOING DOWN

If the house washer drain starts backing up, you get a rooter and clear the drain, right? But some people would just seal it up so it couldn't overflow, instead of clearing the drain, as they should. (Now, WE wouldn't do that, would we, folks?)

But that air break between the washer's drain hose and the house's drain pipe is important.

If there is no air break, and the drain system fills with water, it can actually start siphoning water right through the pump and down the drain. Depending on how bad the drain is backing up, the washer might never fill completely; the solenoid valve will just stay open and water will just keep siphoning straight out the drain. Or, if the drain is a little more clogged and the water is flowing more slowly, the washer might fill and start agitating, but stop agitating after a few minutes and fill some more. This fill-agitate-fill-agitate cycle will continue for as long as the agitate cycle lasts. And since the power to the timer motor is being interrupted, the wash and rinse cycles may seem unusually long.

There is a solution, even if you don't want to root out the drain blockage as you should. Your appliance parts dealer has a drain line vacuum break valve, available for just a few bucks. (Figure G-7) You can cut into your drain line and install one of these vacuum breaks pretty easily.

When the drain line is under pressure, (like when the pump is pumping out) the flapper valve closes and no leakage occurs. When the drain line is under a vacuum (like when the drain is trying to siphon it) the flapper valve opens and air is allowed into the drain line, breaking the siphoning action.

The pump can perform several functions. In all washers, it is used to pump water out of the tub at the end of an agitate or soak cycle. In some washers, it also circulates water during the agitate cycle. It may also provide flush water for a bleach or softener dispenser. Therefore, the pump may be required to pump in two different directions or more during a cycle.

Some brands and/or models accomplish this by using two different pump impellers in one body; the pump body will have two inlets and two outlets. Others use a solenoid-activated butterfly valve in the pump body to re-direct the waterflow. Still others use a direct-reversing pump; the motor driving the pump turns in the opposite direction, and the pump pumps in the opposite direction.

DIAGNOSIS

Sometimes the most obvious answers are the first ones overlooked. If the tub isn't draining, first check the drain system. Check the drain hose to make sure it isn't kinked. Also check any lint filter that may be installed. On some Whirlpool/Kenmore models, there is also a side-check valve at the tub outlet that can get clogged.

There aren't too many things that can go wrong with a pump. The pump bearings can seize, stopping it from turning. The pump can be jammed by socks or other small items. The impeller blades can break off due to junk entering the pump; if this happens, the pump may seize up, or it may just stop pumping. The usual solution is to replace the pump.

But the symptoms of a pump failure are something else altogether.

If the pump locks up, and the motor is still trying to turn it, something's gotta give. If the pump is belt-driven (as it is in many washers) the pulley driving the pump may shear off, or the belt may break. The belt may ride over the locked pulley, or the motor pulley will continue turning under the belt; this will burn the belt and possibly break it. There may even be enough tension on the belt to stop the motor from turning.

The symptoms can be confusing. For example, a common complaint about a Whirlpool belt-drive washer is that it isn't spinning, accompanied by a strong burning smell. The problem is almost always a pump that's locked up. The washer doesn't enter the spin cycle because the spin is interlocked with the drain cycle. This means that the basket won't start spinning until the water is partially drained. The burning smell comes from the rubber belt, which is riding over the motor pulley or locked pump pulley.

NOTE: If you EVER find a broken belt, check for a locked pump, transmission or other pulley before replacing the belt.

If you suspect that something is jamming the pump, drain the tub and pull the hoses off the pump. Look into the hoses and the pump and pull out whatever is jamming it. If you can't see anything jamming the pump, feel around the inside of the pump inlets and outlets with a pair of needlenose pliers. If all else fails, and you still can't find the jam, pull the pump out of the machine and check it.

For specific information about pump replacement or service, see the chapter about your brand.

Although there are a few leaks common to all brands, most brands have leaks that are peculiar to their design. GE, Whirlpool, Maytag, and others all have common and well-known leak areas. After reading this section, see the chapter about specific brands for details.

A common "leak" zone is not a leak at all; the wall drain backs up and overflows onto the floor. This is commonly misdiagnosed as a leak. It can be difficult to diagnose; the problem may be intermittent. Depending on how badly the drain is clogged, there may be a little water or a lot, or it may only overflow every second or third load. While diagnosing a leak, do not be too quick to write this diagnosis off.

If you suspect that your drain is backing up, but you can't quite ever be there at the right time to observe the overflow, try this: wrap some toilet paper around the drain hose just above the wall drain pipe. If it backs up, the paper will get wet. Even if you're not there when it happens and the paper dries out, it will have crinkled up, and you'll know your drain's backing up.

If it isn't the drain, run the machine with a full load. Without moving the machine, get right down on the floor and look under the machine with a flashlight. Try to find the general area where water is dripping to the floor; front or back of the machine, left or right side.

Open the cabinet and look for mineral or soap deposits where there shouldn't be any.

Trace the deposits in the natural direction of waterflow (against gravity or centrifugal force) back to the source of the leak. Fill the machine again and run it through a cycle or two. Be patient; use your eyes and your brains. There is no magic, easy way to detect a leak.

The usual places are:

WATER VALVE: The guts of the fill solenoid valve sometimes will corrode. You may see water leaking from, or rust on the top of the solenoid. (See figure G-7A) Since the valves only open during a fill cycle, this may appear as an intermittent leak. The solution is to replace the valve.

PUMP: Usually from around the pulley seal. Some washer pumps have a hole that allows water to weep out when the seal starts to go bad. The solution is to replace or rebuild the pump.

BLEACH DISPENSERS: Bleach is VERY hard on plastic parts. If the bleach dispenser gets old and brittle, it can crack or break off, and the flush water can leak out.

But since the dispenser may only be flushed at certain times in the cycle, this will appear as an intermittent leak. The solution is to replace the dispenser, or if you don't use it any more, plug the hose and seal the cracked dispenser with RTV (silicone seal.)

HOSES: Though hose leaks are a bit less common than other leaks, any hoses with a few too many miles on them may be suspect. Replace the hose.

TUB: If the tub is rotted through, it's probably time to replace the washer. If a consistent imbalance in the basket has caused it to wear a hole in the tub (not an uncommon experience to old-style GE washers) then you may be able to fix it with an epoxy patch. Ask your appliance parts dealer for an epoxy patch kit.

Besides driving the pump in most washers, the main drive motor has two main functions: to spin the basket and reciprocate the agitator. One motor is used to do both.

Within the transmission there is typically a crank gear and connecting rod arrangement to provide the reciprocating motion to the agitator. However, some designs use a differential gear, slider, eccentric, or other design.

The spin motion comes directly from the rotary motion of the motor, through some clutch arrangement. Usually there is some kind of reduction arrangement in the belt or gearing.

There must also be some mechanism to change between spin and agitate. There are two ways that this is most commonly done.

Some washer designs use solenoids to engage and disengage clutches and transmissions. The solenoid engages a clutch to turn the basket in the spin cycle. For the agitate cycle, a solenoid (sometimes the same one) disengages the clutch and engages the transmission. For specific information see the chapter about your brand.

Many washer designs use a direct-reversing motor. When the motor turns one way, a mechanical arrangement such as a helical shaft, centrifugal clutch or torsion spring engages and spins the basket. When the motor reverses, the brake locks the basket and the transmission engages, so the agitator agitates.

The basket braking arrangement is often a part of the clutch arrangement. Braking is usually "fail-safe" — that is, if the solenoid or mechanical arrangement that engages the spin mode fails, the brake will stop the basket automatically.

For specific information about YOUR washer's drive train, see the chapter pertaining to your brand.

Look closely at the surface of the belt. If you see any of the problems shown in figure G-8, replace it.

Broken or worn out belts are a common problem. See the chapter on your brand for specific details about changing the belt(s) on your model. If you EVER find a broken belt, check for a locked pump, transmission or other pulley before replacing the belt.

If your washer is agitating weakly or not at all, the splines that connect it to the driveshaft may be stripped. It's a fairly common problem. Remove the agitator as described in the chapter specific to your washer. If the shaft is rotating but the agitator is not, replace the agitator or spline insert.

Transmissions in general are pretty bullet-proof, and rarely experience problems beyond a little oil loss. There are exceptions; see the chapter pertaining to your washer.

If your transmission is leaking oil badly, you basically have two options: replace the transmission now, or keep running it until it runs out of oil and dies.

Nobody I know of rebuilds transmissions themselves any more. It is far quicker and easier to just replace it with a rebuilt. See the chapter about your brand for replacement details.

Occasionally, something will break inside the casing and lock the transmission, or prohibit its operation in one mode or another.

The symptoms may be similar to a locked pump; stalled motor, burning belt, etc.

To diagnose this, first unplug your washer. Try turning the motor by hand, or pull the belt so everything rotates. Be careful you don't pinch your fingers between the belt and pulley! Check to see that every pulley that the belt rides is rotating. It should be pretty stiff, but if you can't turn it at all, something is locked up. Disengage the drive system (remove the belt, etc.) Try to turn the transmission drive pulley with your hand. Also check the movement of the pump, and any tensioner or idler pulley that may be present.

Do not try to rebuild your own transmission. Typically, rebuilding requires special tools that drive the cost above that of buying a rebuilt transmission. Rebuilt trannies for the more popular models are inexpensively available from your parts dealer, and usually kept in stock.

There are a few very poor designs out there that are not worth fixing; you are better off scrapping the washer. Due to some parts business politics, I can't mention brand names in this book, but your parts dealer will probably be happy to privately let you know which ones they are.

Sometimes you need to read a wiring diagram, to make sure you are not forgetting to check something. Sometimes you just need to find out what color wire to look for to test a component. It is ESPECIALLY important in diagnosing a bad timer.

If you already know how to read a wiring diagram, you can skip this section. If you're one of those folks who's a bit timid around electricity, all I can say is read on, and don't be too nervous. It will come to you. You learned how to use a VOM in Chapter 1, right?

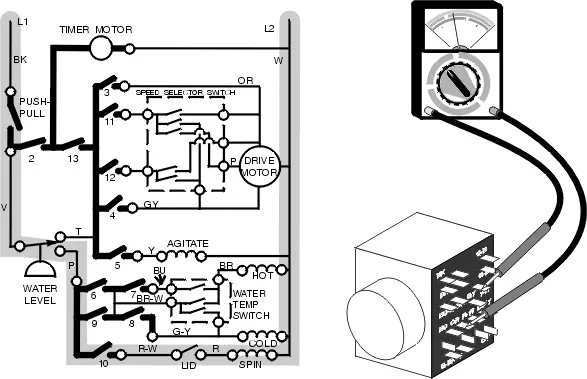

Look at figure G-9. The symbol used to represent each component is pretty universal, and each component should be labelled clearly on your diagram.

A few notes about reading a wiring diagram:

Notice that in some parts of the diagram, the lines are thicker than in other parts. The wiring and switches that are shown as thick lines are inside of the timer.

The small circles all over the diagram are terminals. These are places where you can disconnect the wire from the component for testing purposes.

If you see dotted or shaded lines around a group of wires, this is a switch assembly; for example, a water level, water temperature or motor speed switch assembly. It may also be the timer, but whatever it is, it should be clearly marked on the diagram. Any wiring enclosed by a shaded or dotted box is internal to a switch assembly and must be tested as described in sections 2-6(c) and 2-6(d).

Switches may be numbered on the diagram, but that number will not be found on the switch. Those numbers are there to help you follow the timer sequencing chart. Don't worry about the timer sequencing chart. We are only concerned to see if the switch is opening and closing. We'll let the design engineers worry about exactly when it opens and closes.

To find (and test) a switch with a certain number, look for the color of the wires leading to the switch.

Wire colors are abbreviated; for example, BU means blue, BL or B means black, V means violet, T means tan. If you see a wire color with a dash or a slash, that means — with a — stripe. For example, OR-W means orange with a white stripe; G/P means green with a pink stripe.

NOTE: Green wires are ground wires and MUST be re-connected when removed.

Remember that for something to be energized, it must make a complete electrical circuit. You must be able to trace the path that the electricity will take, FROM the wall outlet back TO the wall outlet. This includes not only the component that you suspect, but all switches leading to it. In Figure G-9(a), L1 and L2 are the main power leads; they go directly to your wall plug.

Let's say you need to check out why the spin solenoid is not working. Following the gray-shaded circuit in figure G-9(a), the electricity flows through the black wire (L1) to the push-pull switch. This switch is located inside of the timer (you know this because it is drawn with thick lines) and it must be closed. The power then goes through the violet wire to the water level switch (which must have a LOW water level,) then through the pink wire back into the timer. Inside the timer, it goes through switch number 10. It then comes out of the timer in a red wire with a white stripe (R-W) that leads to the lid switch (which must be closed.) From the lid switch, it goes through a red wire to the spin solenoid. Finally it leaves the spin solenoid in a white wire, which leads back to the main power cord (L2).

If you're not sure whether a certain switch or component is a part of the circuit you're diagnosing, assume that it is and test it. For example, switches 3,4,11&12 all lead to the motor circuit. If you have a motor problem that you think you've traced to the timer, don't bother trying to figure out which switch goes to which part of the motor. Test all four; if any of the four switches is bad, you will need to replace the whole timer, anyway.

To test for the break in the circuit, simply isolate each part of the system (remove the wires from the terminals) and test for continuity.

For example, to test the spin solenoid in our example, pull the red and white wires off the spin solenoid and test continuity across the solenoid terminals as described in section 2-6(a).

The push-pull switch, and switch number 10 are shown in bold lines, so they are inside the timer. Looking at the diagram, the push-pull switch controls a lot of other things besides the spin solenoid. Since those things are working O.K., we know that the push-pull switch can't be the problem.

For now, let's ignore switch number 10. (Remember: the timer is the last thing you should check; see section 2-5(c).)

That leaves the water level switch, the lid switch, the spin solenoid itself, and the wiring.

Nine times out of ten, a component has gone bad. Test those first. Take power off the machine and check each switch and/or solenoid in the circuit as described in sections 2-5 (a) thru (e).

To check for a wire break, you would pull each end of a wire off the component and test for continuity through it. You may need to use jumpers to extend the wire; for example, if one end of the wire is in the control console and the other end in underneath the machine. If there is no continuity, there is a break in the wire! It will then be up to you to figure out exactly where that break is; there is no magic way. If you have a broken wire, look along the length of the wire for pinching or chafing. If there is a place where the wires move (like near the wigwag of a belt-driven Whirlpool/Kenmore,) check there first. Even if the insulation is O.K., the wire may be broken inside.

INTERLOCKS

Certain safety mechanisms are installed on almost every washer that can lead you to a misdiagnosis if you forget about them.

For example, a Whirlpool washer will pump out water if the lid is open, but it won't spin. So you've just replaced the pump, and you're standing there with the lid open, admiring how well it's pumping out, when you notice it still isn't spinning. You dive right back into the back of the washer, trying to figure out what you forgot to replace...and the only problem is that the lid is up. Don't laugh; I'd hate to admit to you how many times I've done it.

When diagnosing an electrical problem, there are many interlocks in the system that you need to check. For example, if your basket won't spin at all, you will check all the obvious stuff (lid switch, spin clutch solenoid, transmission, etc.) But will you think to check the imbalance switch? If it fails, it may have the same effect as a failed lid switch. When tracing an electrical problem, check your wiring diagram to see if there may be any forgotten switches in the malfunctioning system.

Here are a few of the more common safety interlock mechanisms to watch out for:

LID SWITCH: Mentioned above, it prevents the basket from spinning while the washer lid is open. In some designs, it also prevents the tub from filling or the agitator from agitating while the lid is open. See the note about mercury lid switches in section 2-2.

IMBALANCE INTERLOCK: If the washer has detected a substantial imbalance in the load during the spin cycle, the motor will stop. Usually a buzzer will sound. To reset this interlock, the lid must be opened and closed or the timer turned off and back on. (Presumably, you will redistribute the clothes, but it is not necessary to reset the interlock.)

WATER LEVEL INTERLOCK: On some washers, the basket will not start spinning until the water is nearly pumped out of the tub. The start of the spin cycle is dependent on the pump pumping out water and the water level switch sensing that the water level is low enough.

CAUTION: NEVER BYPASS A SAFETY INTERLOCK. THEY ARE THERE FOR A REASON.

Testing switches and solenoids is pretty straightforward. Take all wires off the component and test resistance across it.

Switches should show good continuity when closed and no continuity when open.

Solenoids should show SOME resistance, but continuity should be good. If a solenoid shows no continuity, there's a break somewhere in the windings. If it shows no resistance, it's shorted.

Water level diaphragm switches are usually shown on a wiring diagram by the symbol in figure G-10. The numbering or lettering of the terminals may differ, but basically all switches are tested the same way.

To test the switch, first fill the tub to the highest water level. Unplug the machine and set the water level switch on the lowest water level setting. Remove the three leads from the switch. Label the wires to make sure you get them back on the proper terminals.

In the example shown in figure G-10, a check for continuity should show the following:

TUB FULL: No continuity from V to P, continuity from V to T.

Re-attach the wires, plug in the machine and set the timer on "spin" or "drain." When the tub is pumped dry, stop the spin cycle and unplug the washer. Remove the wires from the water level switch and test continuity again. With an empty tub, the continuity should be reversed:

TUB EMPTY: Continuity from V to P, no continuity from V to T.

If you do not get these readings, the water level switch is bad, or there's a leak in the air pressure tube leading to it (as described in section 2-2.) Replace the switch or tube.

The labelling of the three water level switch leads is different in just about every brand, but the switch is tested in the same way. See the chapter about your brand for details about the labelling of the switch leads.

The timer is the brain of the washer. It controls everything in the cycle. In addition to telling the motor when and which way to run, it tells any clutch solenoids when to engage, the fill valve when to open, dispenser solenoids when to open, etc.

Most washers still have mechanical, that is, motor-operated timers. Some newer machines have digital timers and control (computer) boards.

Diagnosing digital machines is often a matter of reading the digital fault code or performing a self test. Testing procedures and fault codes for individual models can usually be found on a paper located inside the console.

A mechanical timer is nothing more than a motor that drives a set of cams which open and close switches. Yet it is one of the most expensive parts in your washer, so don't be too quick to diagnose it as the problem. Usually the FIRST thing a layman looks at is the timer; it should be the LAST. And don't forget that timers are electrical parts, which are usually non-returnable. If you buy one, and it turns out not to be the problem, you've just wasted the money.

In a wiring diagram, a mechanical timer may appear in two different ways (Figure G-11). The wiring and switches that are inside the timer will either be drawn with dark lines, or there will be a shaded or dotted line drawn around the timer's internal wiring and switches.

DIAGNOSIS

If the timer is not advancing, well, that's pretty obvious. Replace the timer or timer drive motor, or have it rebuilt as described below.

Timers can be difficult to diagnose. The easiest way is to go through everything else in the system that's malfunctioning. If none of the other components are bad, then it may be the timer.

Remember that a timer is simply a set of on-off switches. The switches are turned off and on by a cam, which is driven by the timer motor. Timer wires are color-coded or number-coded.

Let's say you've got a spin solenoid problem that you think you've traced to your timer. First unplug the machine. Look at your wiring diagram and see which internal timer switch feeds the spin solenoid. (See figure G-12) In this case, the pink colored wire and the red colored wire with a white stripe lead to switch #10 inside the timer. REMOVE those wires from the timer and touch the test leads to those terminals. Make sure the timer is in the "on" position and slowly turn the timer all the way through a full cycle. (On some timers, you cannot turn the dial while it is on. Whirlpool Direct Drive models (chapter 4) are this way.You must simply test the timer one click at a time. Be patient!)

You should see continuity make and break at least once in the cycle; usually many times. If it doesn't, the internal contacts are bad; replace the timer.

A special timer problem occurs only in machines with direct-reversing motors. The Whirlpool Direct-Drive models (Chapter 4) are prone to this confusing problem, though it's not too terribly common. The symptoms are that when you open the lid at the end of the cycle, the tub hasn't drained. You hear the motor running throughout the cycle, but it doesn't spin or drain; you may also notice that you hear it agitating when it's supposed to be spinning.

For the motor to reverse, the timer must interrupt power to it for a moment. When the timer gets worn, this simply doesn't happen. The motor doesn't get a chance to start in the opposite direction, so it continues to run in the same direction (agitate) until something interrupts the circuit and stops the motor. Like you, lifting the lid. You can see how the symptoms might appear to be intermittent and a bit confusing. The solution: replace the timer.

In general, timers cannot be rebuilt by the novice. Check with your parts dealer; if it can be rebuilt, he'll get it done for you. If it's a common one, your parts dealer may even have a rebuilt one in stock.

For the most part, if your timer is acting up, you need to replace it. To replace, mark the wires or note the color codes written on the timer. If you need to, you can draw a picture of the terminal arrangement and wire colors. If possible, change over the timer wires one-by-one; it can be easier. If there are any special wiring changes, they will be explained in instructions that come with the new timer.

The internal wiring for these switches is almost always shown with a shaded or dotted box around them (Figure G-13.)

The lettering inside the box will tell you what terminals to test. For example, with the temperature switch shown in figure G-13 set on "Warm wash, Cold rinse" all the switches marked with a "WC" will be closed. Take power off the machine, and remove all four wires from the switch. Test for continuity between the BU and the BR terminals; you should see good continuity. Test also between the BR-W and G-Y terminals. You should see good continuity.

Now test between the BR-W and BR terminals. There is no WC marking next to the middle switch, so the switch should be open.

You should see no continuity with your VOM. Test the switch similarly for all settings.

A motor that is trying to start, but can't for whatever reason, is using one heckuva lot of electricity. So much, in fact, that if it is allowed to continue being energized in a stalled state, it will start burning wires. To prevent this, an overload switch is installed on motors to cut power to them if they don't start within a certain amount of time.

If the motor is trying to start, but can't, you will hear certain things. First will be a click, followed immediately by a buzzing or "growling" sound. Then, after about 5 to 20 seconds of this sound, another click and the sound will stop. The sounds will keep repeating every minute or two. In some extreme cases, you may even smell burning.

If you hear the motor doing this, but it won't start, disconnect power and take all the load off it. For example, disconnect the drive belt, pump drive system, etc.

Try to start the motor again. If it still won't start, the motor, starting capacitor or speed selector switch is bad. (The speed selector switch may be trying to start the motor in two different speeds at once.) If you have an ammeter, a stalled motor will be drawing 10 to 20 amps or more. Replace the bad component.

If the motor DOES start with the load removed, the pump or transmission may be locked up; See section 2-3 and 2-4(a).

CAPACITOR

Not all machines have external motor starting capacitors.

On machines that do, most external capacitors are mounted piggyback on the motor. (Figure G-14) A few machines have their capacitors mounted separately inside the cabinet, and a few have them mounted in other places, like behind the control console. See the chapter about your machine for details.

If your machine has an external capacitor, unplug the machine and DISCHARGE THE CAPACITOR. BE CAREFUL; IT CAN GIVE YOU A NASTY SHOCK, EVEN IF THE WASHER IS NOT PLUGGED IN! You can discharge it by shorting the two terminals on your capacitor with your screwdriver. Be careful not to touch the metal part of your screwdriver with your hands while you do this.

After discharging the capacitor, disconnect its leads and test it. Set your VOM on Rx1 and touch the two test probes to the two capacitor terminals. Initially, the meter should bounce towards the right of the scale (good continuity), then slowly move back to the left side a bit as the capacitor builds resistance.

Reverse the two probes on the terminals. The meter reading should act the same way. If you do not get these readings, replace the capacitor.

STARTING SWITCH

Only GE-built machines have an external, replaceable current-relay starting switch. See the GE chapter for testing.

Most other machines have a centrifugal starting switch mounted piggyback on the motor. Testing the switch is most easily accomplished by replacing it.

Remember that starting switches are electrical parts, which are generally not returnable. If you test the switch by replacing it, and the problem turns out to be the motor itself, you will probably not be able to return the starting switch for a refund. But they're generally pretty cheap, and if it IS the problem, you just saved yourself the best part of a hundred bucks for a new motor.

MOTOR

If your motor is stalled (buzzing and/or tripping out on the overload switch) and the capacitor, starting switch and speed selector switches test O.K., the motor is bad. Replace it.

Please share our .