Refrigerator Repair & Icemaker Repair

WHIRLPOOL / KENMORE ADC Defrost / Diagnosis

Maximum defrost cycle time is 21 minutes.

First defrost is 6 hours after initial plugin (cumulative compressor runtime.)

Minimum time between defrost cycles is 8 hours.

Maximum time between defrost cycles is 100 hours.

The ADC adjusts the defrost interval according to compressor runtime, and length of the last defrost cycle. ASSUMING that the fridge has been on and running, and the terminating thermostat is closed, defrost is initiated in most models by turning the cold control on and off as follows:

OFF for 15 seconds, then ON for 5 seconds, then

OFF for 15 seconds, then ON for 5 seconds, then

OFF for 15 seconds, then ON for 5 seconds, then turn the cold control off.

The defrost heater should start heating up within 8 seconds.

To terminate defrost, unplug the fridge.

Note that the ADC will only enter the defrost mode if the terminating thermostat is closed. You will hear a click as the relay on the ADC board switches from the "cool" mode to the "defrost" mode. If the terminating thermostat is open, you will hear a second click and the fridge will return to the cooling mode; you probably have a bad terminating thermostat.

If the defrost heater does not come on at all, try initiating defrost as follows:

Unplug the fridge for 30 seconds.

While it is unplugged, turn the cold control off.

Then plug the fridge back in.

The defrost heater should start heating up within 8 seconds.

The ADC board relay will also click as described above.

If the above procedure caused the heater to heat up, the ADC board is probably bad; replace it.

If the defrost heater does not heat up, test the defrost heater and terminating thermostat. You can test them for continuity together, without opening up the evaporator. Find the test plug in the wiring harness with a brown lead and a pink lead (inside the control box.) Unplug the fridge and disconnect the ADC, then test for continuity between this brown lead and any white lead. You are measuring resistance through the heater; you should see some resistance, and some continuity. If not, the heater is bad.

Now test between the brown and pink leads. You are now testing continuity through the terminating thermostat. If the evaporator has been running and the terminating thermostat is cold, you should see continuity. If not, the terminating thermostat is bad.

Appendix A:

Diagnosing defrost problems in ADC-controlled machines

These machines use a very complex "control board" accessible at the right rear of the refrigerator. In addition to defrost functions, this board gets inputs from thermistors and controls the operation of fans, damper doors and heaters throughout the refrigerator, as well as water-in-door, icemaker, ice crusher and auger functions.

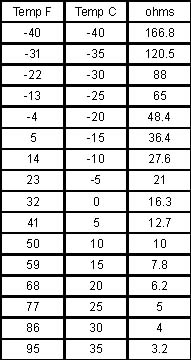

Thermistors are simply variable resistors. The resistance of a thermistor varies inversely with the temperature of the thermistor; the lower the temperature, the higher the resistance. Thus a thermistor can measure the temperature in a space and translate that into an electrical signal that a logic board can use.

For example, if the temperature in a space gets too low, the thermistor will tell the logic board, and the logic board can close an air damper to warm the space a little.

Defrost intervals (time between defrost cycles) are controlled by the frequency and duration of freezer and fresh food door openings, defrost heater runtime and compressor runtime.

Maximum defrost cycle time is 45 minutes.

Minimum time between defrost cycles is 8 hours. (accumulated compressor runtime)

Maximum time between defrost cycles is 60 hours. (accumulated compressor runtime)

If the refrigerator is not defrosting, because of the complexity of the control system, there could be a number of reasons.

Test the defrost heater and terminating thermostat as follows: unplug the fridge, and unplug the blue connector from the control board. Using an ammeter, test the resistance between the blue wire on the blue connector, and the orange wire (pin 9, the last pin) on the J7 connector (this connector is marked N on the board, for "Neutral.") You should see 22 Ohms of resistance. You are testing through the defrost heater and terminating thermostat, so if you get either an open reading or no resistance, one of these components is bad. When you reinstall the blue connector and turn the power back on, the defrost heater should heat up. If not, the terminating thermostat is bad.

There are two thermistors in the evaporator compartment, near the top of the evap. They are a control thermistor and a high-temp thermistor, which basically does the same thing as the terminating thermostat. You can test these thermistors according to the table to the right. However, it is easier to just replace one or both of them. (They are both the same thermistor.)

If the heater, thermostat and thermistors test out OK, replace the main board.

Appendix A: Diagnosing defrost problems in ADC-controlled machines

On the initial plugin, or when power is restored to the fridge after a power outage:

If terminating thermostat is open, the fridge enters a compressor (cooling) cycle.

If the terminating thermostat is closed, the first defrost cycle occurs 1 hour after initial plug-in.

Maximum defrost cycle time is 24 minutes.

Minimum time between defrost cycles is 6 hours. (compressor runtime)

Maximum normal clock time between defrost cycles is 12 hours.

Maximum time between defrost cycles (in "vacation" mode) is 72 hours.

Vacation mode is not entered unless the door has not been opened in at least 24 hours.

Note that the ADC will only enter the defrost mode if the terminating thermostat is closed. If the terminating thermostat is open when defrost is initiated, the ADC board will wait for six minutes and then return to the cooling mode.

ASSUMING that the fridge has been on and running, and the terminating thermostat is closed, defrost is initiated by pressing the door (light) switch at least five times within six seconds.

The defrost heater should start heating up within 8 seconds.

If the above procedure caused the heater to heat up, the ADC board is probably bad; replace it.

If the defrost heater does not heat up, test the defrost heater, terminating thermostat and cold control for continuity as follows:

Unplug the fridge from the wall. Unplug the ADC board from its connector.

Test the connector for continuity between the following leads:

Defrost Heater = DEF TERM (blue) to DEF OUT (brown).

Terminating Thermostat = DEF TERM (blue) to NEUTRAL (lt blue).

Cold Control = COLD CONTROL (orange) to L1 (black).

Replace the defective component.

Appendix A: Diagnosing defrost problems in ADC-controlled machines

ADC Defrost / Diagnosis

Maximum defrost cycle time is approximately 23 minutes.

The ADC adjusts the next defrost interval (time until the next defrost cycle) based on how long the defrost heater was energized during the last defrost cycle. The length of the defrost cycle is determined by the terminating thermostat. Logically, then, the shorter the defrost cycle, the less frost needed to be melted, so the longer the compressor can be run until the next defrost cycle.

To intitate defrost, find the ADC board. In Maytag-built machines, it is inside the temperature control housing, which also contains the food compartment (cold control) and freezer controls.

The ADC board should have six terminals: DEF HTR, COMP, L2, DEF TSTAT, TEST and L1.

Make sure the compressor is running. If you try to initiate defrost without the compressor running, it will cycle through the test mode in two seconds, andthere will not be any current draw through the defrost heater.

Use a jumper wire to short between L1 and test for a few seconds. This will place the unit into a 23-minute defrost mode. The defrost heater will heat up. If you have an ammeter, the heater will be drawing about 4 to 5 amps.

If the above procedure caused the heater to heat up, the ADC board is probably bad; replace it.

If the defrost heater does not energize, test the defrost heater and terminating thermostat as described in section 4-5(f).

Please share our .