Oven, Stove, Range and Cooktop Repair

Lets talk aluminum foil for a minute. If you line the bottom of your oven with it, it can block the airflow within your oven. If you have a convection oven, it really defeats the purpose. But even in an oven with natural convection, it can mess up airflow and cooking and even cause burners to malfunction. If you simply must line the bottom of your oven with foil, at least poke holes in it where there are holes in the oven floor. They're there for a reason.

1) When working on gas cooking equipment, if you've disconnected a gas pipe to replace a valve or other component, always test the pipe joint for leaks when you reassemble it. You can do this by coating the joint with a solution of liquid soap and water and looking for bubbles. Apply it with a brush to make sure you coat the joint thoroughly, and use a mirror to look at the back side of the joint if necessary. Your appliance parts dealer has gas leak testing solution, with a brush built into the cap, made specifically for this purpose.

2) Always de-energize (pull the plug or trip the breaker on) any oven that you're disassembling. If you need to re-energize the oven to perform a test, make sure any bare wires or terminals are taped or insulated. Energize the unit only long enough to perform whatever test you're performing, then disconnect the power again.

3) If this manual advocates replacing the part, REPLACE IT!! You might find, say, a solenoid that has jammed for no apparent reason. Sometimes you can clean it out and lubricate it, and get it going again. The key words here are apparent reason. There is a reason that it stopped - you can bet on it - and if you get it going and re-install it, you are running a very high risk that it will fail again. If that happens, you will have to start repairing your oven all over again. It may only act up when it is hot, or it may be bent slightly...there are a hundred different "what if's." Very few of the parts mentioned in this book will cost you over ten or twenty dollars. Replace the part.

4) Always replace the green (ground) leads when you remove an electrical component. They're there for a reason. And NEVER EVER remove the third (ground) prong in the main power plug! They are especially important in spark ignition systems; the spark electrode will not spark without grounding.

5) When opening the oven cabinet or console, remember that the sheet metal parts have very sharp edges. Wear gloves, and be careful not to cut your hands!

6) If you have diagnosed a certain part to be bad, but you cannot figure out how to remove it, sometimes it helps to get the new part and examine it for mounting holes or other clues as to how it may be mounted.

7) When testing for a 110 volt power supply from a wall outlet, you can plug in a small appliance such as a shaver or blow dryer. If you're not getting full power out of the outlet, you'll know it right away. If you're testing for 220 volt power you need to use the VOM.

8) When splicing wires in an oven, remember that you're dealing with high temperatures. Normal connectors and wire insulation will melt under these conditions. Your parts dealer has high-temp connections, porcelain wire nuts and fiberglass-insulated wire for this purpose.

I want to impress upon you something really important. In electric cooking equipment, you're usually dealing with 220 volt circuits. DO NOT TAKE THIS LIGHTLY. I've been hit with 110 volts now and then. Anyone who works with electrical equipment has at one time or another. It's unpleasant, but unless exposure is more than a second or so, the only harm it usually does is to tick you off pretty good. However, 220 VOLTS CAN KNOCK YOU OFF YOUR FEET. IT CAN DO YOUR BODY SOME SERIOUS DAMAGE, VERY QUICKLY. DO NOT TEST LIVE 220 VOLT CIRCUITS. If you have a heart condition, epilepsy, or other potentially serious health conditions, well...hey, it's just my opinion, but you shouldn't be testing 220 volt circuits at all. It's not worth dying for.

Find yourself a good appliance parts dealer. You can find them in the yellow pages under the following headings:

- Appliances, Household, Major

- Appliances, Parts and Supplies

- Ovens Stoves, Domestic

- Appliances, Household, Repair and Service

Call a few of them and ask if they are a repair service, or if they sell parts, or both. Ask them if they offer free advice with the parts they sell. (Occasionally, stores that offer both parts and service will not want to give you advice.) Often the parts counter men are ex-technicians who got tired of the pressures of in-home service. They can be your best friends. However, you don't want to badger them with too many questions, so know your basics before you start asking questions.

Some parts houses may offer service, too. Be careful! There may be a conflict of interest. They may try to talk you out of even trying to fix your own oven. They'll tell you it's too complicated, then in the same breath "guide" you to their service department. Who are you gonna believe, me or them? Not all service and parts places are this way, however. If they genuinely try to help you fix it yourself, and you find that you're unable to, they may be the best place to look for service. Here's a hot tip: after what I just said, if they sold you this book, then I'll just about guarantee they're genuinely interested in helping do-it-yourselfers.

When you go into the store, have ready the make, model and serial number from the nameplate of the oven. Chapter 3 has information on how to find the nameplate. On some models, you will also need the lot number to get the right part, so if there is one on the nameplate, write that down, too.

Most of the tools that you might need are shown below. Some are optional. The reason for the option is explained.

ELECTRICAL PLIERS or STRIPPERS and DIAGONAL CUTTING PLIERS: For cutting and stripping small electrical wire

VOM (VOLT-OHM METER): For testing electrical circuits. If you do not have one, get one. An inexpensive one will suffice, as long as it has both "AC Voltage" and "Resistance" (i.e. Rx1, Rx10) settings on the dial. It will do for our purposes.

BUTT CONNECTORS, CRIMPERS, WIRE NUTS and ELECTRICAL TAPE: For splicing small wire. When splicing wire on ovens, you must make sure you use high-temp connections, such as porcelain wire nuts, high-temp terminals and fiberglass insulated wire.

ALLIGATOR JUMPERS (sometimes called a "CHEATER" or "CHEATER WIRE"): Small gauge (14-16 gauge or so) and about 12-18 inches long, for testing electrical circuits. Available at your local electronics store. Cost: a few bucks for 4 or 5 of them.

SCREWDRIVERS: Both flat and Phillips head; two or three sizes of each. It's best to have at least a stubby, 4- and 6-inch sizes.

NUTDRIVERS: You will need at least 1/4″ and 5/16″ sizes. 4- and 6-inch ones should suffice, but it's better to have a stubby, too.

SNAP-AROUND AMMETER: For determining if electrical components are energized, without cutting into the system. Quite useful; but a bit expensive, and there are alternate methods. If you have one, use it; otherwise, don't bother getting one.

EXTENDIBLE INSPECTION MIRROR: For seeing difficult places beneath the oven and behind panels.

CORDLESS POWER SCREWDRIVER OR DRILL/DRIVER WITH MAGNETIC SCREWDRIVER AND NUTDRIVER TIPS: For pulling off panels held in place by many screws. It can save you lots of time and hassle.

Many home handymen are very intimidated by electricity. It's true that diagnosing and repairing electrical circuits requires a bit more care than most operations, due to the danger of getting shocked. But there is no mystery or voodoo about the things we'll be doing. Remember the rule in section 2-1; while you are working on a circuit, energize the circuit only long enough to perform whatever test you're performing, then take the power back off it to perform the repair. You need not be concerned with any theory, like what an ohm is, or what a volt is. You will only need to be able to set the VOM onto the right scale, touch the test leads to the right place and read the meter.

In using the VOM (Volt-Ohm Meter) for our purposes, the two test leads are always plugged into the "+" and "-" holes on the VOM. (Some VOMs have more than two holes.)

Set the dial of the VOM on the lowest VAC scale (A.C. Voltage) over 120 volts. For example, if there's a 50 setting and a 250 setting on the VAC dial, use the 250 scale, because 250 is the lowest setting over 120 volts.

If you're testing 220 volt circuits, use the lowest scale over 220 volts.

Touch the two test leads to the two metal contacts of a live power source, like a wall outlet or the terminals of the motor that you're testing for voltage. (Do not jam the test leads into a wall outlet!) If you are getting power through the VOM, the meter will jump up and steady on a reading. You may have to convert the scale in your head. For example, if you're using the 250 volt dial setting and the meter has a "25" scale, simply divide by 10; 120 volts would be "12" on the meter.

Don't let the word "continuity" scare you. It's derived from the word "continuous." In an electrical circuit, electricity has to flow from a power source back to that power source. If there is any break in the circuit, it is not continuous, and it has no continuity. "Good" continuity means that there is no break in the circuit.

For example, if you were testing an ignitor to see if it was burned out, you would try putting a small amount of power through the ignitor. If it was burned out, there would be a break in the circuit, the electricity wouldn't flow, and your meter would show no continuity.

That is what the resistance part of your VOM does; it provides a small electrical current (using batteries within the VOM) and measures how fast the current is flowing.

For our purposes, it doesn't matter how fast the current is flowing; only that there is current flow.

To use your VOM to test continuity, set the dial on (resistance) R x 1, or whatever the lowest setting is. Touch the metal parts of the test leads together and read the meter. It should peg the meter all the way on the right side of the scale, towards "0" on the meter's "resistance" or "ohms" scale. If the meter does not read zero ohms, adjust the thumbwheel on the front of the VOM until it does read zero. If you cannot get the meter to read zero, the battery in the VOM is low; replace it.

If you are testing, say, an ignitor, first make sure that the burner leads are not connected to anything, especially a power source. If the ignitor's leads are still connected to something, you may get a reading through that something. If there is still live power on the item you're testing for continuity, you will burn out your VOM instantly and possibly shock yourself.

Touch the two test leads to the two bare wire ends or terminals of the ignitor. You can touch the ends of the wires and test leads with your hands if necessary to get better contact. The voltage that the VOM batteries put out is very low, and you will not be shocked. If there is NO continuity, the meter won't move. If there is GOOD continuity, the meter will move toward the right side of the scale and steady on a reading. This is the resistance reading and it doesn't concern us; we only care that we show good continuity. If the meter moves only very little and stays towards the left side of the scale, that's BAD continuity; the ignitor is no good.

If you are testing a switch, you will show little or no resistance (good continuity) when the switch is closed, and NO continuity when the switch is open. If you do not, the switch is bad.

Ammeters are a little bit more complex to explain without going into a lot of electrical theory. If you own an ammeter, you probably already know how to use it.

If you don't, don't get one. Ammeters are expensive. And for our purposes, there are other ways to determine what an ammeter tests for. If you don't own one, skip this section.

For our purposes, ammeters are simply a way of testing for continuity without having to cut into the system or to disconnect power from whatever it is we're testing.

Ammeters measure the current in amps flowing through a wire. The greater the current that's flowing through a wire, the greater the density of the magnetic field, or flux, it produces around the wire.

The ammeter simply measures the density of this flux, and thus the amount of current, flowing through the wire. To determine continuity, for our purposes, we can simply isolate the component that we're testing (so we do not accidentally measure the current going through any other components) and see if there's any current flow.

To use your ammeter, first make sure that it's on an appropriate scale (0 to 10 or 20 amps will do). Isolate a wire leading directly to the component you're testing. Put the ammeter loop around that wire and read the meter. (Figure 2-E)

For example, let's say you're trying to tell if the oven is using any current anywhere. Clamp the ammeter around just one of your main wall power leads. If the meter shows any reading at all, something in the oven is using power.

Sometimes you need to read a wiring diagram, to make sure you are not forgetting to check something. Sometimes you just need to find out what color wire to look for to test a component. It is ESPECIALLY important in diagnosing self-cleaning ovens.

Usually your wiring diagram is either pasted to the back of the oven, or else contained in a plastic pouch inside the backguard or inside the leg of the oven, near the broiler door (see section 3-6)

If you already know how to read a wiring diagram, you can skip this section.

Each component should be labelled clearly on your diagram. Look at figure 2-F. The symbols used to represent each component are pretty universal.

Wire colors are abbreviated and shown next to each wire. For example, Y means a yellow wire, PK means pink, R means red. Black is usually abbreviated BK, blue is usually BU. GR or GN are green, GY is gray.

A wire color with a dash or a slash means --- with a --- stripe. For example BU-W means blue with a white stripe, T/R means tan with a red stripe.

A few notes about reading a wiring diagram:

Notice that in some parts of the diagram, the lines are inside a dashed box. These switches and wiring are inside of the timer or other block of switches. In some wiring diagrams, wiring and switches inside a timer or other switchblocks are drawn with lines that are thicker than the rest of the wiring.

The small white circles all over the diagram are terminals. These are places where you can disconnect the wire from the component for testing purposes. The small black circles indicate places where one wire is connected to the other. If two wires cross on the diagram without a black dot, they are not connected.

Switches may be numbered or lettered. Usually the terminals on the outside of the timer or switch are stamped or printed with markings that you will see on the wiring diagram.

To test a switch, mark and disconnect all the wires. Connect your ohmmeter to the two terminal leads of the switch you want to test. For example, in figure 2-F, if you want to test the door switch, take power off the machine, disconnect the wires from it and connect one test lead to COM and one to NC. Then flick the switch back and forth. It should close and open. If it does, you know that contact inside the switch is good.

Remember that for something to be energized, it must make a complete electrical circuit. You must be able to trace the path that the electricity will take, FROM the wall outlet back TO the wall outlet. This includes not only the component that you suspect, but all switches leading to it, and sometimes other components, too.

Electric circuits in gas ovens are 110 volt circuits. Most electric cooking equipment has two circuits; 110 volt and 220 volt. (see figure 2-G) In a 220 volt circuit, L1 to L2 will measure 220 volts, but L1 to N or L2 to N will measure 110 volts. In this simplified circuit diagram, notice that only the heating elements operate on 220 volts. The timer, lights and other accessories operate on 110.

Let's trace an actual cleaning circuit. Figure 2-H shows a pretty complex wiring diagram. It is for a self-cleaning gas convection oven, with spark surface ignitors. When tracing an actual circuit, especially in more complex diagrams, it may be worthwhile to make a couple of photocopies of the wiring diagram, and trace circuits with a colored highlighter pen, to keep yourself straight.

Following the gray-shaded circuit, note that the electricity "flows" from L1 to N. This tells you that it is a 110 volt circuit. Let's say the oven door is not locking during the cleaning cycle. Since the locking mechanism is interlocked with the heating circuit, the oven will not reach cleaning temperature either.

Let's start at the lock motor and find out which switches feed electricity to it. One of the leads goes directly to N. Tracing the other lock motor lead, we first end up at the "C" terminal of the 4-position selector switch. Looking at the switch for the chart, the "C" to "LM" contacts are closed when the "clean" button is depressed on the switch. So we need to test that switch for proper operation. (see section 2-6(a))

Continuing with the circuit, we leave the selector switch through the "LM" terminal, and enter the oven thermostat through the "6" terminal. Power then leaves the thermostat through the "5" terminal, so we need to check for continuity between terminals "5" and "6" of the thermostat. Since it is a thermostatic switch, only heat will open the switch, so we only need to test it for continuity. If it is not opening when it gets to temperature, that will cause different symptoms from what we're trying to diagnose.

Likewise terminals "4" and "3" of the clock (timer.) Make sure the switch is closed and test for continuity between those terminals.

Switch B, switch A, and the cool-down switch are all activated when the locking motor turns. They are shown in the diagram in their "normal state." So continuing with our circuit, if the locking motor is not turning, you need to check switch "B" for continuity between the "COM" and "NC" terminals. If there is no continuity, it might mean the switch is bad. It might also mean that the switch was not returned to its "normal" state the last time it was activated!

You need to examine the switch carefully to determine what the problem is. If the locking motor stopped turning before the switch unlocked, you've got other problems. You will need to trace other circuits in the diagram to figure out what.

From the "COM" terminal of switch "B," the circuit goes back through the door switch to L1. The door switch feeds several other oven circuits, too, so unless there's something else not working, we can eliminate that as the problem. Note that in its "normal" state, the oven light is on and the door is open. The door must be closed to close the switch that feeds electricity to the thermostats and heating circuit.

To check for a wire break, you would pull each end of a wire off the component and test for continuity through the wire. You may need to use jumpers to extend or even bypass the wire; for example, if one end of the wire is in the control console and the other end in underneath the machine. If there is no continuity, there is a break in the wire! It will then be up to you to figure out exactly where that break is - there is no magic way. If you have a broken wire, look along the length of the wire for pinching or chafing. The most likely place you will find burnt wires is inside the back panel. If there is a place where the wires move, check there too. Even if the insulation is O.K., the wire may be broken inside.

Most components are tested simply by removing power and placing a resistance meter across them. However some need to be tested with a VOM while energized. An ammeter is a safer way to test energized circuits if you have one, especially testing 220 volt circuits. Occasionally, if the component is inexpensive enough, it's easier to just replace it and see if that solves the problem.

Following is a primer on how to test each individual component you might find in any given oven. Diagnostic information is covered in chapters 4, 5 & 6.

Testing switches is pretty straightforward. Take all wires off the component and test continuity across it as described in section 2-4(b).

Switches should show good continuity when closed and no continuity when open. Flick the switch back and forth with the resistance meter attached and see if the contacts are opening and closing.

NC means "normally closed;" in other words, if nothing is touching the switch, you should see continuity between the terminals. NO means "normally open" and with the switch at rest, you will see no continuity through it.

SELECTOR SWITCHBLOCKS

A selector switchblock, located in the control panel, is a group of switches all molded into one housing. In your oven, a switchblock might be used to allow you to choose a cooktop heat setting, for example, or a cleaning cycle instead of a baking cycle. When you select an option, "high heat" for example, you are de-selecting the other options, for example "medium heat." This is why you would use a switchblock instead of individual switches.

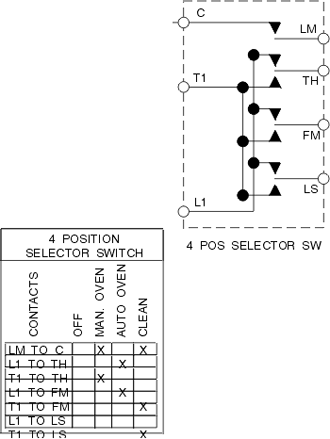

Testing switch blocks is much like testing timers. You must look at the wiring diagram to see which of the terminals will be connected when the internal switches are closed.

Keep in mind, however, that you must also know which of the internal switches close when an external button is pressed. When you press one button on the switchblock, several of the switches inside may close at once.

To test a switchblock, in addition to the wiring diagram, you must have a chart that gives you this info. Usually this is a part of the wiring diagram.

Using the diagram and chart in figure 2-J, lets say we want to test contacts "T1" to "FM" for proper operation. We see that with the "clean" button pressed, these contacts inside the switchblock should be closed. With the "off" button pressed, these contacts should be open. Remove the wires and put the resistance meter probes on those two terminals. Then push the "off" and "clean" buttons alternately, to see if the switch opens and closes.

Test other switches similarly. Figure out when they're closed, when they're open, and test resistance while operating the switch.

If the switchblock is bad, replace it.

Analog, or electro-mechanical controls are covered thoroughly in this service manual. Solid-state digital controls, clocks and thermostats are not. Although error (fault) codes for most major brands may be found in Chapter 7, usually diagnosis consists of simply replacing circuit components until you find the bad one.

Usually the problem turns out to be a bad oven sensor, stuck or defective keypad, ERC (clock) unit or a circuit board. Sensors are not bad, but the other parts are expensive and electrical. Electrical parts are usually non-returnable, so you could go through a lot of money trying to solve the problem.

If you have a problem that you think you've traced to a solid-state circuit, try Chapter 7, but if you are in any way unsure of your diagnosis, call a factory-authorized technician.

Do not confuse this with electro-mechanical "digital" clocks, in which the "digits" are printed on a wheel that turns. These can be tested and rebuilt or replaced as described in this chapter.

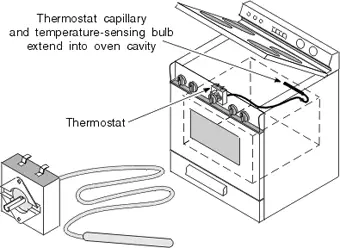

A thermostat is simply a switch or a gas valve that opens and closes according to the temperature it senses. There might be several different kinds of thermostatic switches in any given oven; high-limit stats to prevent overheating, cleaning thermostats and cool-down stats for the oven cleaning cycle, etc.

In an oven, the main control thermostat body is located in the main control panel, (see chapter 3) but there is a liquid-filled temperature sensing bulb that extends down into the oven. (see figure 2-K) Heat in the oven increases the pressure in the bulb, and a capillary carries the pressure back to the body of the thermostat, where it opens and closes switch contacts or a gas valve.

Thermostats are either gas or electric; pressure from the capillary either closes an electrical switch or opens a gas valve.

That is the simplest form of a main control thermostat. If only all of them were that easy. If there is an automatic oven cycle, main control thermostats must also be wired through the timer. And if there is a cleaning cycle, they must be either bypassed or adjusted for the higher temperatures of that cycle. That's where you start to get dual-control thermostats, thermostats with twelve leads, and other complexities. Some control a pilot in addition to the main burner. Some even control two levels of the same pilot.

Main control thermostats are about the most expensive commonly-replaced parts in an oven. Usually the first thing a novice thinks is that the thermostat has quit working. It should be the last thing you conclude, after you have checked out everything else in the system.

The liquid inside the bulb and capillary of an oven thermostat is usually a mercury or sodium compound or some other such nasty and dangerous stuff. It can literally explode on contact with air. So when you replace an oven thermostat, do not cut open the capillary or bulb, and dispose of the old thermostat properly. The definition of "properly" varies between jurisdictions, but check with your appliance parts dealer or local fire department hazardous materials professionals.

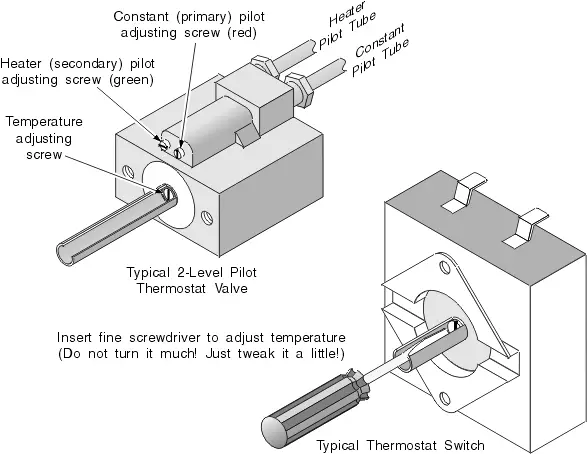

ADJUSTING THERMOSTATS

The oven is adjusted by a small adjusting screw in the center of the oven thermostat valve stem. (see figure 2-L) Remember that the thermostat keeps the temperature within a certain range, and usually there will be a 20 or 30 degree spread. In other words, if you set the thermostat at 350 degrees, you want the heating system to cycle on if the temperature is below 340 degrees, and off when the temperature reaches about 360 degrees. Don't forget, too, that heat rises, so the top of the oven might be warmer than the bottom of the oven.

Get a good calibrating thermometer from your appliance parts dealer...they're pretty inexpensive. With nothing else in the oven, place it in the middle of the oven, where you can see it through the oven door glass. Let the burner cycle on and off at least twice, then observe the low temperature (when the burner cycles on) and the high temperature (when the burner cycles off.) Adjusting the screw adjusts both temperatures up or down.

Clocks and timers operate on 110 volt circuits, whether on gas or electric ovens. The important thing to remember about clocks in an oven unit are that often the thermostat controls are first wired through the timer. This can make them rather complex devices to troubleshoot, remove and install. Also, if you are troubleshooting a no heat complaint in an oven with an automatic cycle, the first step is always to check the timer controls. (An automatic cycle is one that allows you to program in advance the start and stop times and of a desired baking cycle.)

A prime example: I once got an oven service call right after Thanksgiving, where the complaint was no heat. The woman who greeted me was the ultimate Susie homemaker; everything was spotless in HER kitchen. Including the oven, which looked new, but this gal swore she'd owned it since it was new 35 years before, and by golly she knew it inside and out and didn't know why two ovens out of three suddenly didn't work. My first question: did she have family over for Thanksgiving? Yup. Does she ever use the timer function? Nope. Were her daughters or their kids using the oven? Yes again.

I reset her automatic cycle controls (which, coincidentally, were only on two of three ovens) and collected the thirty dollars for a service call, thank you very much.

Testing clocks and timer controls is just like testing switchblocks, except that the switches are opened and closed mechanically by cams inside the timer. You must have a wiring diagram to determine which terminals are connected when a switch inside the timer closes. Put a resistance meter across those terminals and advance the clock to determine if the switch is opening and closing. If the clock motor doesn't run or the switches don't open and close as they are supposed to, replace the timer. To replace, mark the wires or tag the wires with the terminal it goes on. If you need to, you can draw a picture of the terminal arrangement and wire colors. If possible, change over the timer wires one-by-one...it can be easier. If there are any special wiring changes, they will be explained in instructions that come with the new timer.

Clocks and timers can usually be rebuilt. Sometimes they have to send it away and it can take several weeks. Ask your appliance parts dealer for details.

Electric heater elements and ignitors are tested by measuring continuity across them as described in section 2-5(b). A good heater will show continuity, but quite a bit of resistance. A bad heater will usually show no continuity at all. Replace heater elements if they show no continuity.

Heating elements use a lot of electricity compared to other electrical components. The switches that control them sometimes need to be built bigger than other kinds of switches, with more capacity to carry more electricity.

The switches involved in running a heater or ignitor can be too big to conveniently put inside the control console or timer. Besides that, there are safety considerations involved in having you touch a switch that carries that much electricity directly, with your finger.

The way they solve that problem is to make a secondary switch. A little switch activates an electromagnet, which closes a big switch that carries the heavier current load. This is called a relay. (Figure 2-M) To test a relay, like any other switch, you test the opening and closing of the switch, but additionally you need to test for continuity through the coil.

Transformers are two coils wrapped around a common metal core. (Figure 2-N) Test for continuity through each coil. Also test for continuity between each lead and the metal core. This would indicate a short.

Solenoids are similar to relays; while a relay closes a switch, solenoids perform some mechanical function, like locking an oven door. They should be tested the same way. The coil should show SOME resistance, but continuity should be good. If a solenoid shows no continuity, there's a burnt or broken wire somewhere in the coil.

Please share our .